Among the few professions where hard work does not always equal success is over-the-road trucking. A driver might be active throughout the week, cover long distances, and still lose money and miles by the time his payroll is cut. A different driver who drives the same lanes with the same equipment might get a stronger declaration for the week solely because he was more organized. The dividing line is rarely lady luck. Most of the time, it is systems.

An OTR week turns into success only after a specific OTR weekly checklist is observed, not merely by hustle. Knowledge, planning, and systems that can be executed repeatedly, save the driver a lot in the form of invisible fuel, miles, energy, and attention. On the other hand, without a properly organized list of tasks for the week, truck drivers are likely to cause little efficiency losses that simply add up over time and push OTR productivity downwards.

In this article, the truck driver checklist crafted specifically for the long distance hauling of goods and long haul trucking is introduced. It is not an inspirational tool but a working scheme that aims to help drivers to maximize the number of miles, to increase the efficiency of drivers, and to secure the profitability of truck driving on a week-to-week basis.

The rules are the same for company drivers, lease operators, and owner-operators. Their pay structures may vary, but the basics of a successful trucking business stay unchangeable.

Why OTR Productivity Is Measured in Weeks, Not Days

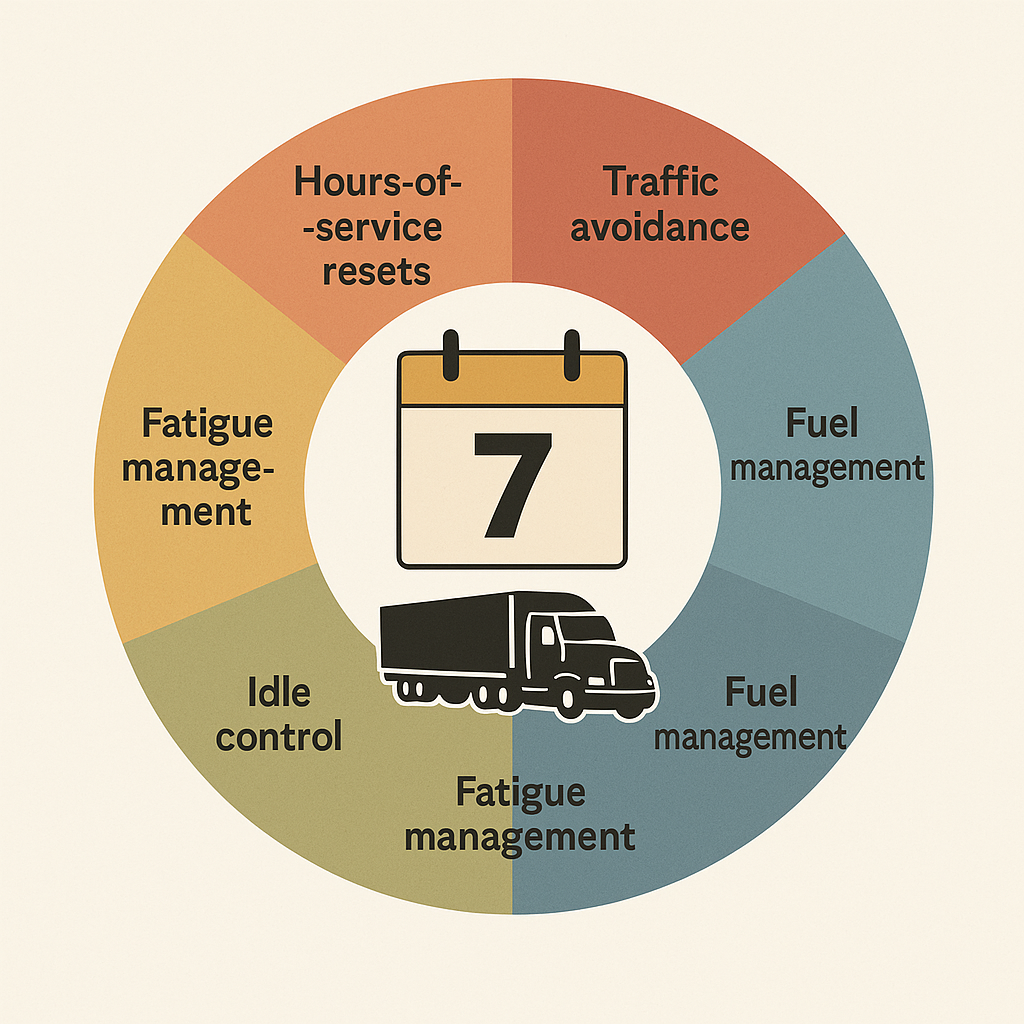

Many drivers focus on daily execution: wake up, run the route, deliver, repeat. Daily discipline matters, but true OTR productivity is counted in seven days.

A week is a reflection of how hours-of-service resets are used, when traffic is absorbed or avoided, how fuel is managed, how idle time is controlled, how fatigue is lost or gained, and how miles become cash.

Drivers who think in days act therefore they react. Drivers who prefer to think on a weekly basis are the ones who prevent problems. That difference alone is the one that determines whether you maximize miles or slowly bleed them away.

This weekly perspective is especially relevant when applying owner-operator tips focused on long-term efficiency rather than daily output.

How Drivers Unknowingly Lose Miles

Definitely, it is unlikely to lose a bunch of miles at once. Mostly they go missing in a silent way through a series of tiny, repeated inefficiencies.

Current Mileage Leaks

- Starting late after resets

- Habitual driving into peak congestion

- Searching for parking at the day’s end

- Poor appointment buffer planning

- Overextending hours early in the week

Seeing an issue as a single entity is hard, you might argue. When put together, however, they clearly are the main reasons why driver efficiency is lost and the overall OTR performance is lacking.

How Drivers Secretly Lose Money

Unlike other issues, money loss is very hard to find because it remains hidden in regular decisions.

Typical Financial Leaks

- Fueling according to convenience instead of strategy

- Too much idling while waiting

- Buying daily food from truck stops

- Interruptions from unnecessary maintenance

- Weak time management trucking habits

Drivers discover their losses only later, when the week is over and they do not meet their numbers. By knowing such patterns and dealing with them, drivers can reduce the cost of operations and also can learn to save money consistently through trucking.

The Core Rule of a Productive OTR Week

Each of the checklists for drivers that you find in this guide is based on just four principles:

- Predictability is better than speed

- Consistency beats intensity

- Preparation triumphs reaction

- Recovery is better than burnout

These principles are the backbone of professional driving suggestions that can be applied to long distance trucking effectively.

Step 1: Weekly Reset — Clearing the Previous Week

A good week begins before the truck is even driven.

Weekly Reset Checklist

- Review last week’s total miles

- Identify delays and causes

- Reset your sleep schedule

- Organize documents and your cab

- Mentally close the previous week

Bypassing this step, more-or-less, ensures that last week’s issues will be repeated.

Step 2: Mileage Strategy — Protecting Paid Hours

Miles are not equal to distance. They are the driving time that can be used.

Mileage Strategy Checklist

- Choose the right times for productive driving

- Steer clear of predictable congestion

- Move the hours instead of forcing them

- Protect the hours early in the week

Clean Miles vs. Dirty Miles

| Mile Type | Characteristics | Weekly Impact |

| Clean miles | Steady flow, low stress | High OTR productivity |

| Dirty miles | Stop-and-go, delays | Lost time and fuel |

Drivers who protect clean miles regularly outrank peers without driving them more fatigued.

Step 3: Route Planning Beyond Navigation Apps

Navigation apps demonstrate the routes but not the outcomes.

Efficient OTR Route Planning

- Plan fuel stops ahead

- Account for terrain and weather

- Add intentional buffers

- Identify alternative routes

Drivers relying solely on old GPS programs sacrifice efficiency for comfort and, as a result, inefficient OTR performance is.

Step 4: Time Management in Load Execution

Waiting is a must, wasted waiting is optional.

Load Execution Checklist

- Arrive early

- Prepare paperwork in advance

- Limit idle time

- Use delays for rest or planning

Good time management in trucking is one of the most underrated trucking techniques for enhancing weekly results.

Stage 5: Fuel Discipline and Cost Awareness

Fuel is the biggest controllable expense in terms of OTR.

Weekly Fuel Discipline Checklist

- Be aware of regional price patterns

- Avoid emotional fueling

- Reduce off-route detours

- Monitor idle time

Fuel Strategy Comparison

| Strategy | Weekly Result |

| Reactive fueling | Higher costs |

| Planned fueling | Stable savings |

This is where drivers consistently save money trucking without sacrificing performance.

Eco-Driving for OTR Class 8 Trucks – Fuel Saving Tips

Stage 6: Food, Energy, and Driver Condition

A tired driver loses money faster than a slow one.

Weekly Energy Management Checklist

- Plan food storage for the week

- Reduce truck stop dependence

- Maintain hydration

- Protect sleep consistency

Energy management directly affects driver efficiency, reaction time, and safety in long distance hauling.

Stage 7: Mental Load and Focus Control

Mental fatigue is an invisible cost.

Reducing Mental Load

- Limit unnecessary notifications

- Separate work and rest zones

- Use checklists instead of memory

- Maintain predictable routines

Less mental load improves decision-making quality throughout the week and supports sustained OTR productivity.

OTR Productivity as a System, Not an Effort

OTR driving is not hard about working hard, and in long-haul trucking, efficiency tends to shoot up when drivers create their own space by reducing friction in their weeks. Friction, on the other hand, manifests itself through poor timing, unplanned stops, ineffective routing, and weak time management habits.

Efficient OTR performance thrives in predictability. Drivers know how their week will go; therefore, they protect focus, fuel, and hours-of-service. That, in turn, drives up their efficiency and reduces reactive decisions that cause lost miles.

OTR Productivity Drivers vs Productivity Killers

| Factor | Efficient OTR Outcome | Productivity Loss |

| Planned driving windows | Higher OTR productivity | Missed paid hours |

| Weekly structure | Stable driver efficiency | Reactive driving |

| Predictable routines | Lower fatigue | Burnout risk |

| Time management trucking | Consistent miles | Lost miles |

Reducing Costs Trucking Without Cutting Corners

Cost reduction through trucking thrives best when waste is taken out, not comfort. Fuel discipline, controlled idling, planned routing, and structured food routines are the natural ways to lower expenses.

The concept of cost control cannot be dissociated from the concept of truck driving profitability. Any penny that is saved due to efficiency starts accumulating, thanks to the increase in profit with no extra workload.

American Transportation Research Institute (ATRI)

An Analysis of the Operational Costs of Trucking

https://truckingresearch.org/research/operational-costs-of-trucking/

Cost Control vs Cost Cutting

| Approach | Short-Term Result | Long-Term Impact |

| Cost cutting | Temporary savings | Fatigue and errors |

| Cost control | Stable savings | Higher driver efficiency |

| Idle reduction | Lower fuel use | Improved profitability |

Maximizing Profits Trucking Through Consistency

The profit comes from trucking sales not from the chase of a peak load. The base for profit is consistency.

Predictable miles, stable fuel spend, reliable routines, and controlled recovery form the base of a strong truck driving business. Peaks without structure often lead to losses the following week.

Long Haul Trucking as a Business Model

Success in long haul trucking is based on treating driving as a business, whether you are a company driver or not.

The business-minded truckers’ questions are:

- Is OTR productivity improving week to week?

- Are costs controlled or postponed?

- Is driver efficiency stable?

- Is this operation scalable?

Driver Mindset vs Business Mindset

| Perspective | Driver Mindset | Business Mindset |

| Focus | Today’s load | Weekly outcome |

| Decisions | Reactive | Planned |

| Productivity | Miles driven | Efficient OTR |

| Profit view | Gross pay | Net profitability |

Stage 9: End-of-Week Review — Locking in Progress

Most drivers stop when the week ends. Productive drivers review.

End-of-Week Checklist

- Total miles driven

- Total operating costs

- Delays encountered

- One adjustment for next week

This review transforms experience into strategy and supports long-term truck driving profitability.

Further Standing Point: A Weekly OTR System, the Most Efficient Extension of Driving Lanes and Earnings

Most of the drivers think that mileage losses or income drops are quite arbitrary. But, in fact, the majority of the cases of losing miles and money are due to an unstructured OTR weekly routine rather than bad shipment or poor luck. A constructive OTR system is just like a rock that swallows the minor upsets before they blossom into big measurable losses.

Here is the place where practical trucking tactics turn from theory into a specific tool for going operational. When weekly planning, fuel discipline, time management trucking habits, and recovery routines are synchronized, driver efficiency remains unchanged, even during unpredictable times. Rather than facing the daily problems, drivers implement a framework that is under control and protects both miles and income.

For owner-operators particularly, this organized scheme down the road is a form of passive cost control. Owner-operator tips mainly target equipment or rates, yet the major benefit in the long run is the overcoming of the expenses that are not seen but eaten by the revenues. Systematic approaches go with the flow cost trucking while also ensuring the workload remains strikingly realistic and sustainable.

At last, making high profits trucking does not mean working harder or for a longer time. Rather, it means the removal of the friction from the week, having the stability of the performance, and also seeing the trucking business as a process that can be repeated, on the contrary to it being a daily survival fight.

Final Thoughts: Control Beats Hustle

OTR trucking will always include uncertainty: weather, reroutes, delays.The distinction between productive drivers and others is, indeed, not luck. It is control.

This weekly productive OTR checklist provides a structure to protect miles, manage energy, reduce costs trucking, and stabilize income. When applied consistently, it brings turning long-distance hauling from a reactive survival mode to a controlled, efficient truck-driving business.Boats are not just sailed.

They are planned, protected, and earned.

FAQ — Weekly OTR Productivity and Profitability

1. How does a weekly checklist help drivers avoid losing miles and money?

A weekly checklist creates structure around planning, driving windows, fuel usage, and recovery. This structure prevents small inefficiencies from compounding, which is the main reason drivers lose miles and money over time.

2. Are these trucking tips useful for both company drivers and owner-operators?

Yes. While pay structures differ, the fundamentals of OTR productivity, time management trucking, and driver efficiency apply equally to company drivers, lease operators, and owner-operators.

3. Why is OTR productivity better measured weekly instead of daily?

Daily performance does not reflect how resets, congestion, fuel strategy, and fatigue affect income. Weekly measurement reveals whether the OTR weekly routine supports consistent miles and controlled costs.

4. How does driver efficiency affect truck driving profitability?

Driver efficiency determines how much paid driving time is preserved versus wasted. Efficient routines reduce idle time, improve routing decisions, and support reducing costs trucking without sacrificing performance.

5. Is maximizing profits trucking only about higher rates and better loads?

No. Maximizing profits trucking is primarily driven by consistency, predictable execution, and cost control. Stable systems often outperform higher-paying loads that come with inefficiencies.

6. What makes these professional driving tips different from general advice?

These professional driving tips focus on systems, not motivation. They are designed to be repeatable, measurable, and adaptable to long distance hauling under real-world conditions.